Designer water

The notion of Designer Water should not be a new concept, but to many it is.

Think about this for a moment. You can buy a dress shirt off the rack which fits but not perfectly, or you can get a designer shirt tailored to your body which will make heads turn. Designer clothing has a similar function compared to designer recycled water.

Depending on where you live and what level of treatment is performed at a wastewater treatment plant near you determines the type of recycled water available.

All recycled water must meet strict regulations, as mandated by federal and state standards. Usually that means turbidity must be below 2.0 NTU (Nephelometric Turbidity Units – scattering light is used for measurement) and there must be a residual chlorine level to ensure adequate disinfection (this is where salinity is introduced). Continuous monitoring equipment must be installed and data recorded. It appears to be a rather simple and automated process.

But not all recycled water is created equal.

It starts with the source water – the water that leaves the treatment plant. For a treatment plant to discharge their effluent (treated wastewater) they must abide by a National Pollutant Discharge Elimination System (NPDES) permit which dictates what quality of water can leave the plant on its way to a receiving waterway. Generally, the water leaving the plant must be cleaner than the water being discharged to.

Think of it it like this: if a treatment plant is on a pristine mountain stream, then the water that would be discharged to that stream must be pristine as well.

A water reclamation facility is then positioned on the discharge pipe, called an outfall and that’s where the work begins. Depending on the treatment process, disinfected final effluent will be taken in and can be pumped through a dual-media filter containing sand and anthracite, while turbidity is continuously monitored. Suspended solids in the water are removed, sometimes a coagulant can be added if turbidity gets too high to aid in capturing of the particulate in the water. This is one of many processes that fall under Tertiary treatment.

There are other methods besides sand/anthracite coal filtration. These include activated carbon and reverse osmosis.

If the treatment plant is conventional, meaning the water isn’t processed to a standard to remove nitrogen (nitrification / denitrification), then the recycled water that passes through the reclamation facility will also be high in nitrogen. And we all know that plants love nitrogen (fertilizer).

Recycled water fit for irrigation of plants

This is our first type of designer water. Recycled Water fit for irrigation of plants. Water for golf courses, football and baseball fields, farms, airports, street medians, colleges, sod farms, etc. This water, usually high in nutrients means less fertilizer needs to be applied which is always a good thing.

Costs are cut for farmers and plants grow like crazy.

Recycled water fit for oil refinery cooling towers

If oil refineries use raw delta water in their cooling towers then they can also use tertiary treated recycled water, and thus it becomes another source of designer water.

Recycled water fit for toilets

In some LEED certified infrastructure, there are dual-plumbed buildings that use recycled water for flushing toilets. There by saving precious potable water for human consumption instead of as carrier water to whisk our wastes away.

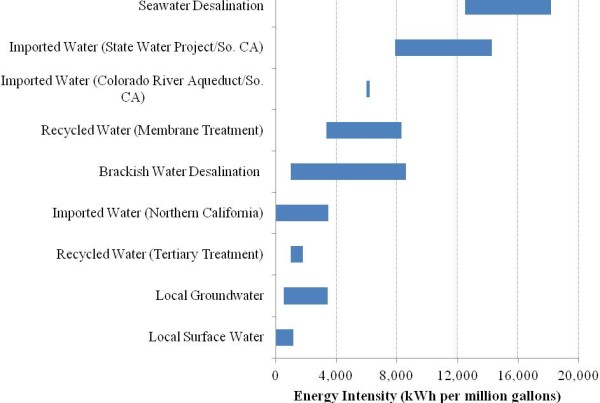

When it comes to Indirect Potable Reuse(IPR) or Direct Potable Reuse(DPR), reverse osmosis membranes are usually used, but they come with high energy cost as water is pumped at high pressures over a microfiltration membrane. See the energy use graphic below from the Pacific Institute.

Membrane treated recycled water, such as with reverse osmosis uses nearly twice as much energy as Tertiary Treatment, but is still significantly cheaper than importing water from the Colorado River and the State Water project (pumping the water around) and then 3-4 times cheaper than desalinating seawater. Desalination is a topic for another day.

Recycled water for indirect potable reuse

This is a topic I have discussed before, and one that has been in service in Orange County since 1978 at Water Factory 21, and more recently since 2008 at the Groundwater Replenishment System. Recycled water is passed through a reverse osmosis filtration system and is then injected into the ground or pumped to a reservoir where it is held for a length of time and allowed to mix with the other water already in that holding vessel. Then it is pumped out and treated to drinking water standards for human consumption.

Recycled water for direct potable reuse

This is the cat’s meow of recycled water. Recycled water so clean it can be directly blended with the current water supply and then treated at a drinking water treatment plant before being plumbed to our homes. If Kevin Costner can do direct potable reuse in the 1995 movie Waterworld, then why don’t we?

Leave a Reply