This is the second part to our series “Meet the Agency Behind The Fill Station – City of Brentwood.”

Water Resource Recovery Facilities are the future and the City of Brentwood has been on the scene since their new facility was built in 2003. There is more to this agency than what any recycled water hauler sees when they drive through the fill station. I received an exclusive tour with Wastewater Operations Manager Casey Wichert and was very impressed with their streamlined processes, making them an excellent example agency for others to follow.

Located 55 miles east of San Francisco in the far east bay region of the San Francisco Bay Area, situated at the foot of the rolling foothills of Mount Diablo and on the the California delta. Brentwood is well known for his agriculture production in cherries, corn and peaches. Many of the farms have since been replaced by suburban developments, raising population from 23,000 at the turn of the century to over 58,000 today.

Their entire flow is treated to state of California Title 22 standards, as required for sewage treatment plants in the delta. Their power requirements are met by a renewable and sustainable solar array, and pending construction of a three-million-gallon storage tank could be a nearly zero discharge facility from May to October. The fact that the treatment plant can do this with such a limited staff is impressive. Even the operations manager gets his hands dirty in the process.

Daily operation of the treatment plant is run by 12 people – 4 operators, 2 mechanics, 1 electrician, 2 lab techs and 3 collections workers. It takes the whole group to run things smoothly. Every operator is on-call one weekend a month. They take an iPad home and can operate the plant from the tablet. When problems arise, automated systems alert the on-call operator and they can generally solve the issue from home.

City of Brentwood – Water Resource Recovery Facility

The class IV Water Resource Recovery Facility (WRRF) was built in 2002-2003. The city provides sewer service to over 58,000 people who live within city limits. Residents, restaurants and businesses generate about 3.5 million gallons of sewer water a day and the WRRF converts that into about 2.9 million gallons of tertiary filtered recycled water. The entire flow meets strict state of California Title 22 standards.

Foul air from headworks and solids handling are pumped through two beds of wood chips, like this one.

As I walk in, there is one thing missing that everyone thinks about with a ‘poo plant’. This place doesn’t smell. A large ventilation system draws foul air from the headworks and solids handling processes and filters it through two large fields of wood chips, about the size of two tennis courts. Microbes in the chips eat the awful smelling air leaving cleansed air to waft into the environment.

Our tour started in front of the two bar screens, enclosed in stainless steel. This equipment captures trash – fruit labels, flushable wipes, condoms – and squeezes out the water and drops the trash into a dumpster. Then the sewer water flows to a grit washer where things like asphalt, sand and other heavy in-organics drop out of suspension. This grit then drops into another dumpster. Both will later end up at a landfill.

“I enjoy showing the kids this part of the tour because they always get grossed out!”

From here the magic happens. The water goes through a tank called the denitrification zone. It’s an anoxic mixing chamber where bugs eat the nutrients in the water, without the addition of oxygen. This helps to reduce nutrient loadings when it reaches the oxidation ditches.

It is gravity fed over to two above ground 2.5 million gallon tanks each with two large variable frequency drives (VFD) driven propellers which add oxygen to the water as it goes around 4 passes on what they call a “raceway”. During this process, the poo in the water is broken down by microscopic bugs, and the water begins showing signs of clarity.

After the oxidation ditch, it’s off to the clarifiers where clear water trickles over weirs and the sludge that settles at the bottom is pumped to a belt filter press (BFP).

In the BFP, the sludge is thickened, hydraulically pressed, dried and is safe enough to be handled with bare hands.

“I enjoy showing the kids this part of the tour because they always get grossed out,” quipped Casey. I was grossed out too and I work in this field.

After the clarifiers, the water takes a trip through a sand filter, dosed with some chlorine and routes its way through another 3 pass raceway for disinfection. When asked if the water is clean enough to drink, Mr. Wichert said, “if the zombie apocalypse happens today, I’ll drink this water tomorrow.” The water is crystal clear and passes every laboratory test they throw at it. But until the zombie apocalypse happens, recycled water is not approved for human consumption.

“We’re regulated by the Central Valley Regional Water Quality Control Board. As a treatment plant on the delta our water quality limits are very stringent,” Casey continued. Just by looking at the water in the contact tank it all made sense. It looked like pristine mountain snow water, like something you’d expect to see in Lake Tahoe or at the pool in a high end resort in Hawaii.

From here, the water is ready to be fed to the recycled water pipeline or discharged to Marsh Creek. While standing on the Marsh Creek Regional Trail, a paved multi-use trail, “Sometimes we are the only water source in Marsh Creek,” Casey said. “If you walk 50 yards up stream you’ll notice the water clarity isn’t that great, but from this point going down stream, you can really see the difference. I’ve been told this is best fishing spot in Brentwood!”

Sustainable Power

The WRRF is powered by a 1 Megawatt renewable and sustainable solar array built by Solar City. Solar City installed and maintains the array through a Power Purchase Agreement. Casey mentioned there is a parking lot shade structure at the Sunset Park Athletics Complex, across the street, which also provides power for the plant.

Zero Discharge

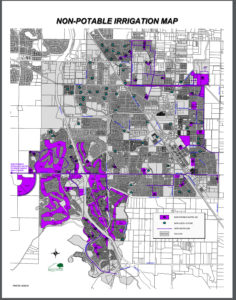

Not only is the City of Brentwood one of the fastest growing recycled water fill stations (by volume), but they also operate a non-potable water distribution pipeline. The non-potable pipeline has so much demand on it between 5-7:30AM that raw delta water must be purchased from the East Contra Costa Irrigation District (ECCID) as make-up water to keep the recycled water pumps from sucking the treatment plant dry.

When the planned storage tank is built, they could save recycled water during peak flows and use it in the morning hours, which could make them become a zero discharge facility up to 40% of the year – something all state agencies should strive for as climate change has a bigger impact on our water future. Due to the treatment plant’s diurnal flow, about 1.5 million gallons a day (MGD) is flowing into the front of the plant at 5AM, but demand for irrigation water is high so an additional 1MGD is needed to meet the needs of the non-potable distribution system.

There are 69 parks and the city maintains over 190 acres of landscaped areas. The recycled water from the treatment plant provides about 10% (~ 120 million gallons) of the overall needs of the non-potable pipeline over the course of a year. Once the storage tank is constructed, they’ll have access to an additional ~1700 ac-ft/year (554 million gallons/year) for park and street median landscaping for recycled water.

To alleviate this problem, last year during the peak of the 2015 drought, City of Brentwood submitted plans to the state to build a 3 million gallon recycled water storage tank. The City anticipates the final environmental review of the project by the National Marine Fisheries Service and Department of Fish and Wildlife this year, which should allow construction to begin early in 2017.

The water resource recovery facility at the City of Brentwood should be a model treatment plant for any agency looking to meet stringent water requirements while employing a highly skilled and professional staff, making recycled water available for free to the community and displaying excellent customer service skills. The lack of odors and sense of cleanliness in every area of the process makes this WRRF one of great intrigue. Thank you Casey for spending time showing off your awesome water resource recovery facility. Keep up the good work guys, keep that recycled water flowing.

Contact Information:

City of Brentwood Wastewater Treatment Plant

2201 Elkins Way

Brentwood, CA 94513

Phone: (925) 516-6000

Fax: (925) 516-6001

Leave a Reply