What does it take to be a Water Resource Recovery leader? Easy, first recover as much water from wastewater influent, second utilizing the resources in the waste to do something sustainable, third recover power used by some renewable process, and fourth, be a leader while doing so.

Who comes to mind when this applied? Delta Diablo.

Located in Antioch, California, Delta Diablo is a water resource recovery leader. They create high quality recycled water for parks, schools, sporting facilities and industrial use. They receive fats, oils and grease from restaurants and a local commercial rotisserie establishment to aid in biogas production in digesters and also installed two massive solar arrays to generate clean electricity from the sun. On top of that, Delta Diablo is the lead agency for recycled water policy change in the western United States and are staying tuned in to their local communities in the process.

But first, why do we change our mindset of a wastewater treatment plant into a water resource recovery facility? The response is simple. It just makes sense. We need to view these important assets in our communities for what they actually do. Recovering resources is that thing.

Delta Diablo began to transform the industry sixteen years ago with the State’s first industrial recycled water facility. Dean Eckerson, Resource Recovery Services Director at Delta Diablo said “It’s our duty and responsibility to our customers.”

Delta Diablo provides resource recovery services for the City of Antioch, City of Pittsburg and the unincorporated community of Bay Point, serving nearly 200,000 people. They process 12 million gallons a day of wastewater and turn it into a variety of reusable things. Delta Diablo also operates a Household Hazardous Waste collection facility to keep toxins out of the environment, such as old home and garden products – automotive fluids, paint, personal care, E-waste and a variety of other things.

But that’s not all, Delta Diablo is also responsible for street sweeping– “it’s an important pollution prevention function provided” to their communities.

Recycled Water

When it comes to reusing water, Delta Diablo is seen at near the top. Situated next to the Delta Energy Center (Calpine, Pittsburg) Power Plant Project, Delta Diablo is required to provide recycled water for power plant cooling towers. Calpine built Delta Diablo’s State-of-the-Art Recycled Water Facility in 2000. Recycled water is plumbed to the energy centers and used to circulate through the cooling towers to cool exhaust steam from their turbine generators.

90% of the recycled water produced at Delta Diablo is pumped to two power plants – Los Medanos Energy Center which produces 550MW and Delta Energy Center which produces 880MW power.

The remaining 10% of recycled water produced is plumbed through a pipeline that extends deep into Pittsburg and Antioch and provides for landscape irrigation at two golf courses (Delta View Golf Course in Pittsburg and Lone Tree Golf Course in Antioch), 12 city parks, 16 schools in Pittsburg Unified School District, City Hall and Civic Park in Pittsburg. The recycled water pipeline was strategically placed to be close to parks and sports fields so that when they were ready to utilize recycled water, it was already available.

Delta Diablo operates a residential recycled water fill station which gave away 2,000,000 gallons to nearly 500 permitted users in 2015. The Board of Directors said they provide this “service on a complimentary basis for users to supplement their existing irrigation water supplies.”

Energy

Six years ago, just as many Bay Area homeowners saw the benefits of installing solar at home, Delta Diablo brought those ambitions to fruition. Five large solar panel shade structures were built, providing 450 kW for their plant operations building, cutting a large percentage of their power needs. The array was setup over the employee parking lot, keeping employee cars cool under the blazing sun.

On the treatment plant side, the anaerobic digester (think of it like your gut) produces methane gas which is used in a cogeneration facility to produce 800 kW. This power is utilized in the treatment to keep the treatment plant moving.

Recently, their co-digestion process was upgraded to receive Fats, Oils and Grease – F.O.G. as it is known in the industry – which helps produce more methane in their digester. By contracting with local grease haulers, Delta Diablo can receive up to 10,000 gallons per day, 5 days a week. This has virtually eliminated any grease build up in their collection system as restaurant F.O.G. is injected into the digester where it goes to work immediately.

Three digesters receive this slurry of sludge, FOG and food scraps and is mixed – all of which aid in biogas creation. This operational change improved the quality of the biogas.

Greg Kester, Director of Renewable Resource Programs at CASA said “There has been a steady increase in co-digestion, especially with FOG and in some cases, food wastes. New costs for co-digestion of FOG are pretty minimal, generally. But through the use of existing digesters, new anaerobic digesters generally don’t have to be built, and there are new options like converting the biogas to transportation fuel (that may help make co-digesting cost positive).”

Solids

Digested material from the digesters, now called Biosolids is made up mostly of organic materials. These are then land applied after a quick trip through a dewatering unit called a centrifuge.

A pilot demonstration project called CANDO – Coupled Anerobic-anoxic Nitrous Decomposition Operation, “is a new treatment process that removes and recovers energy from ammonia nitrogen sidestreams, specifically the centrate from sludge dewatering devices such as from centrifuges,” says Public Information Manager, Angela Lowrey.

Dr. Yaniv Scherson

The recovered gas is called Nitrous Oxide – yes, the same gas you’d expect to see in the latest Fast and Furious movie used to propel cars to unbelievable speeds. When it comes to generating power however, it can be slipped in with methane gas to produce more power in a cogeneration engine.

CANDO was developed by Dr. Yaniv Scherson of Stanford University. “A lot of processes use the anammox bacteria to convert ammonia to nitrogen gas,” says Amando Roa, environmental compliance engineer. “CANDO adds a twist by converting ammonia to nitrous oxide. The pilot will determine how much ammonia can be removed and how much nitrous oxide can be recovered.”

Funding for the project comes from the TomKat Center for Sustainable Energy at Stanford, as well as from the National Science Foundation Engineering Research Center for Reinventing the Nations Urban Water Infrastructure (ReNUWIt) and grants from the National Science Foundation and Veolia Water.

Source: BAB2E

Delta Diablo is a part of a regional coalition made up of 19 agencies across the San Francisco Bay Area called “Bay Area Biosolids to Energy” (BAB2E). This coalition strives to ‘create a local sustainable solution to biosolids management by utilizing the remaining energy’ in biosolids. Just because the organic material has already gasified, doesn’t mean it should be discarded at a landfill. Unfortunately, there are increasingly restrictive regulations on what can be used with the biosolids.

Leadership

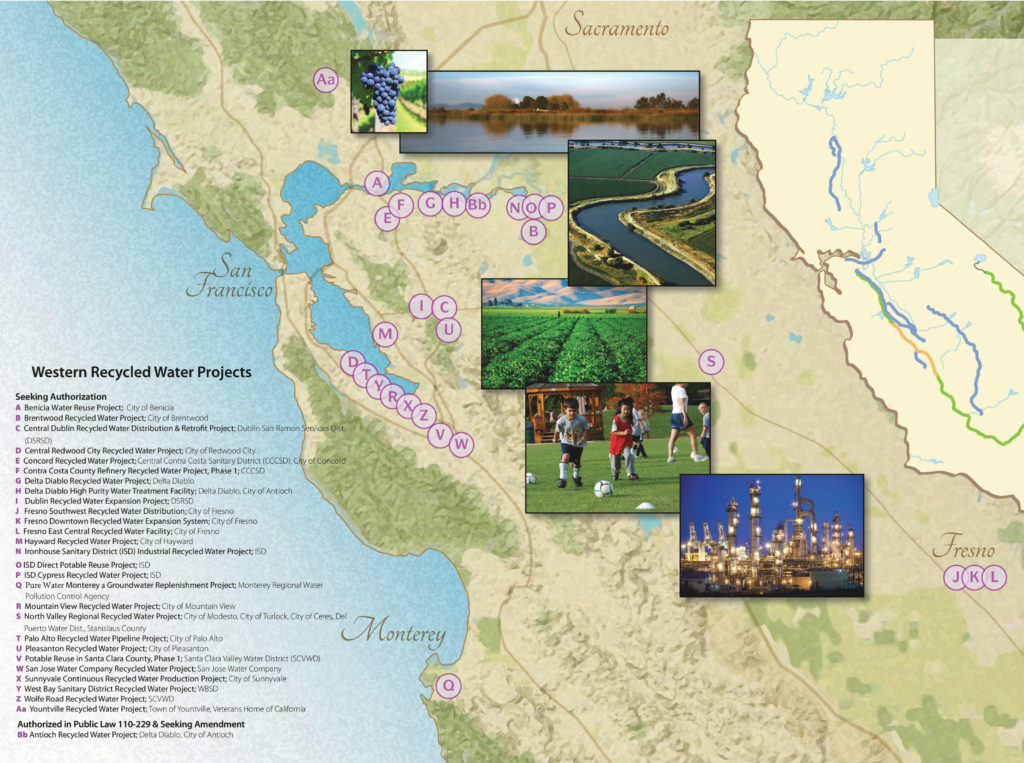

When it comes to Recycled Water projects in the western United States, look no further than the Western Recycled Water Coalition (WRWC). Since its inception, Delta Diablo has been the lead agency behind this group of 24 agencies in California, Washington, New Mexico and Hawaii, representing over 4 million people.

WRWC has successfully secured $38 million in federal funding to construct eight projects and prepare feasibility studies for 14 other projects. For 2016 alone, there are 34 projects in the pipeline totaling $1.5 billion in project cost but creating 197,350 acre feet (64.3 billion gallons) of water. A list of those projects is available here.

Source: Western Recycled Water Coalition

There is a lot that goes into being a Water Resource Recovery leader. Delta Diablo has exemplified that through sharing what they’ve done with RecycledH2O. If you’re in the area, I encourage you to tour their facility to learn about the awesome things they are doing to advance the industry.

Contact Information:

Delta Diablo (http://www.deltadiablo.org)

2500 Pittsburg-Antioch Hwy

Antioch, CA 94509

phone: 925.756.1900

fax: 925.756.1961

0 Comments

1 Pingback