UPDATE: 7/29/2022

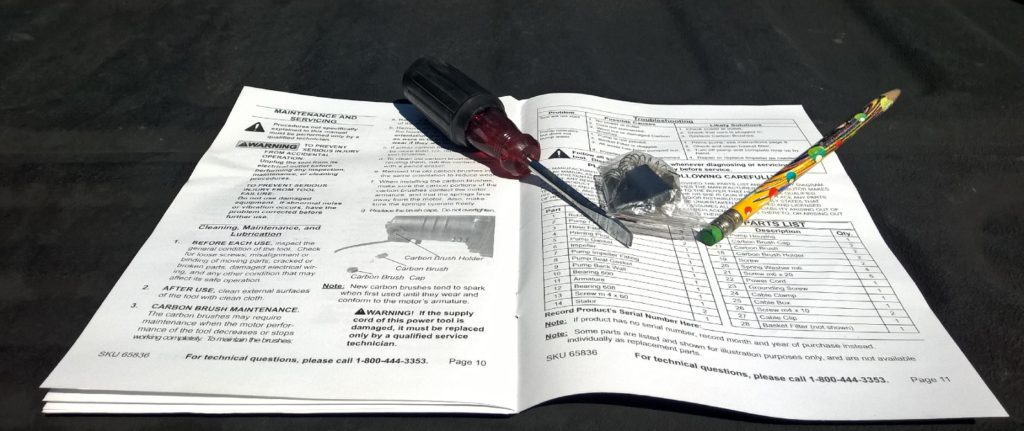

If you bought a Pacific Hydrostar Portable Utility Pump – Model 65836 – from Harbor Freight you may have noticed extra parts in the box and a label on the pump that says “Check brushes after every 100 hours of use and replace as needed.”

What does this label mean and why should you care? The motor has something called ‘Carbon Brushes’ inside which help to ‘excite’ the motor to make it spin. These will wear down over time and cleaning them every now and then can keep your pump running smoothly. Read on to find how to perform preventative maintenance on your utility water pump to ensure its reliability in the future.

UPDATE:

Harbor Freight no longer lists this specific pump on their website, but as a 1250GPH utility water pump, its’ specific carbon brushes are EXTREMELY hard to find. But, at a recent trip to LOWE’S, I discovered the UtilityTech Utility Pump looks almost exactly the same except for minor re-branding and learned the “Q1CZ-900C” Carbon Brushes available on Amazon.com for $11.20 is a perfect replacement.

The procedure below is a reprint from the owners manual for pump, found on pages 10 – 11 under the section titled “Carbon Brush Maintenance.”

Tools required for this job:

1 – flat head screw driver

1 – Pencil eraser

2 – Spare brushes for Pacific Hydrostar Portable Utility Pump – Model 65836 (if applicable)

The carbon brushes may require maintenance when the motor performance of the tool decreases or stops working completely.

To maintain the brushes:

| 1. Remove the brush cap on each side of the motor housing (do one side at a time). | |

| 2. Remove the carbon brushes from the housing. Keep track of which orientation the old carbon brushes were in to prevent needless wear if they will be reinstalled. | |

| 3. If either carbon brush is worn down by more than ½, replace both carbon brushes.

In the photo, a new carbon brush is behind the used brush. About 1 millimeter of carbon has worn away. |

|

| 4. To clean old carbon brushes before reusing them, rub the contact areas with a pencil eraser.

The carbon comes off like graphite (similar) and the brush becomes noticeably cleaner. |

|

| 5. Reinsert the old carbon brushes in the same orientation to reduce wear. | |

| 6. When installing the carbon brushes, make sure the carbon portion of the armature, and that the springs face away from the motor. Also make sure the springs operate freely. | |

| 7. Replace the brush caps. Do not over tighten. |

Note: New carbon brushes tend to spark when first used until they wear and conform to the motor’s armature.

Repeat the process on the other side and put everything back together. Below are some photos from that side.

After cleaning the brushes, I put the pump back to together and unloaded another tank of recycled water onto my yard. The pump sounded noticeably quieter, it was getting quite loud before. It also wasn’t sparking as much as before and this maintenance definitely made the pump work and sound smoother.

If you need more carbon brushes, the suggestion is to just buy a new pump. With a 20% coupon at Harbor Freight this pump is easily $60.

Time to complete: 5 minutes.

Thanks for this info.

Do you know where new brushes can be purchased? Is there a part number?

I don’t have any part numbers. The only thing I have found is this: https://www.mrcarbonbrush.com/65836_marine_pump_motor_brushes/p2644628_15713301.aspx

Harbor Freight doesn’t sell these pumps anymore.

Per Rick –

I did find a different site. http://www.carbonbrush.com/springloaded21.htm

This site has numerous brushes. I purchased that measure .25”x.375” x .75” Graphite, with an eared cap. I installed them and the pump worked. If I order them again, I going to order longer ones such as 1 to 1.125”.

Good luck.